APEX Transmissions' Extensive Stockholding Ensures Reduction in Downtime for End User

Posted on 19/03/24

APEX Transmissions' Extensive Stockholding Ensures Reduction in Downtime for End User

The Situation

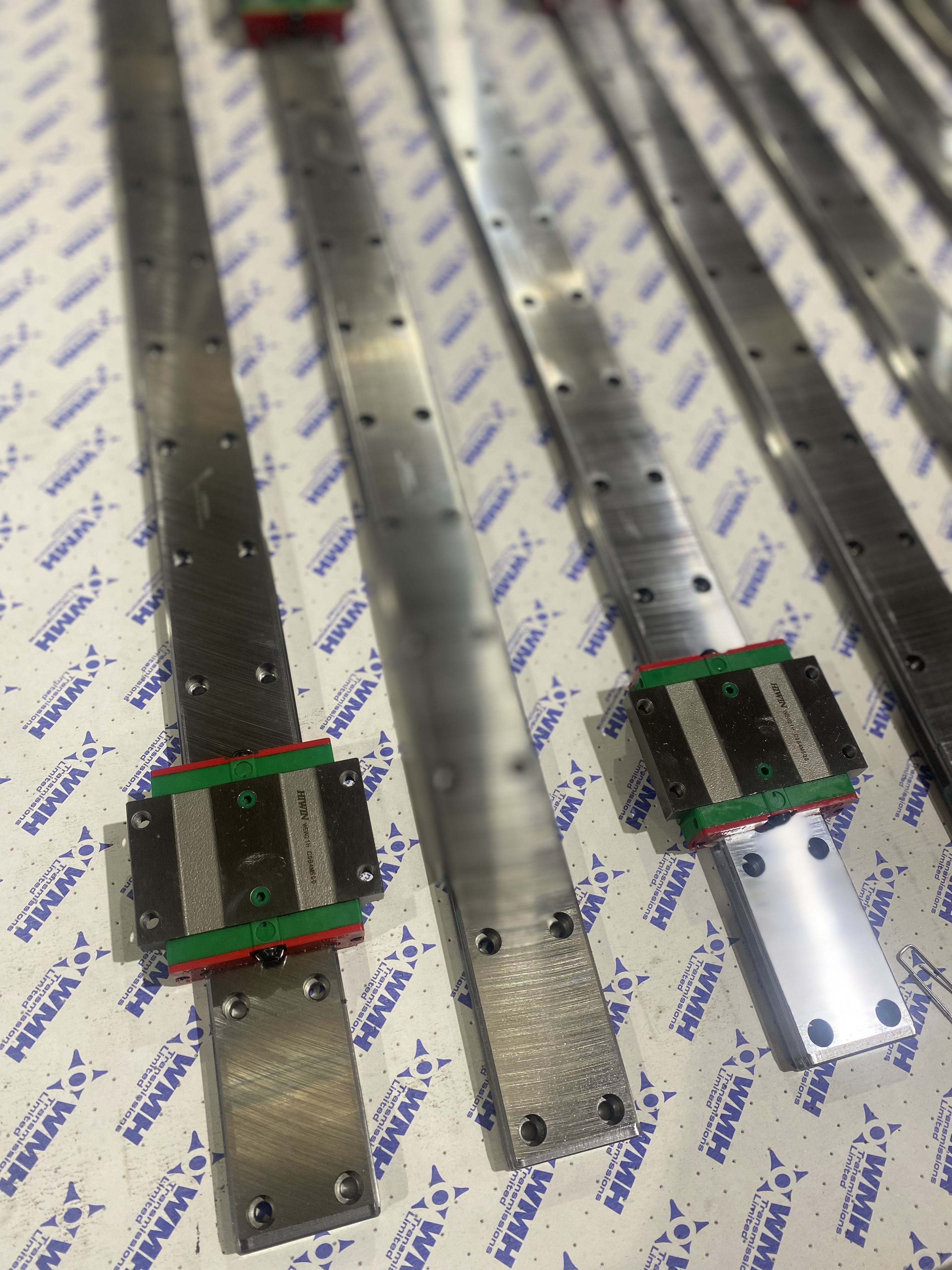

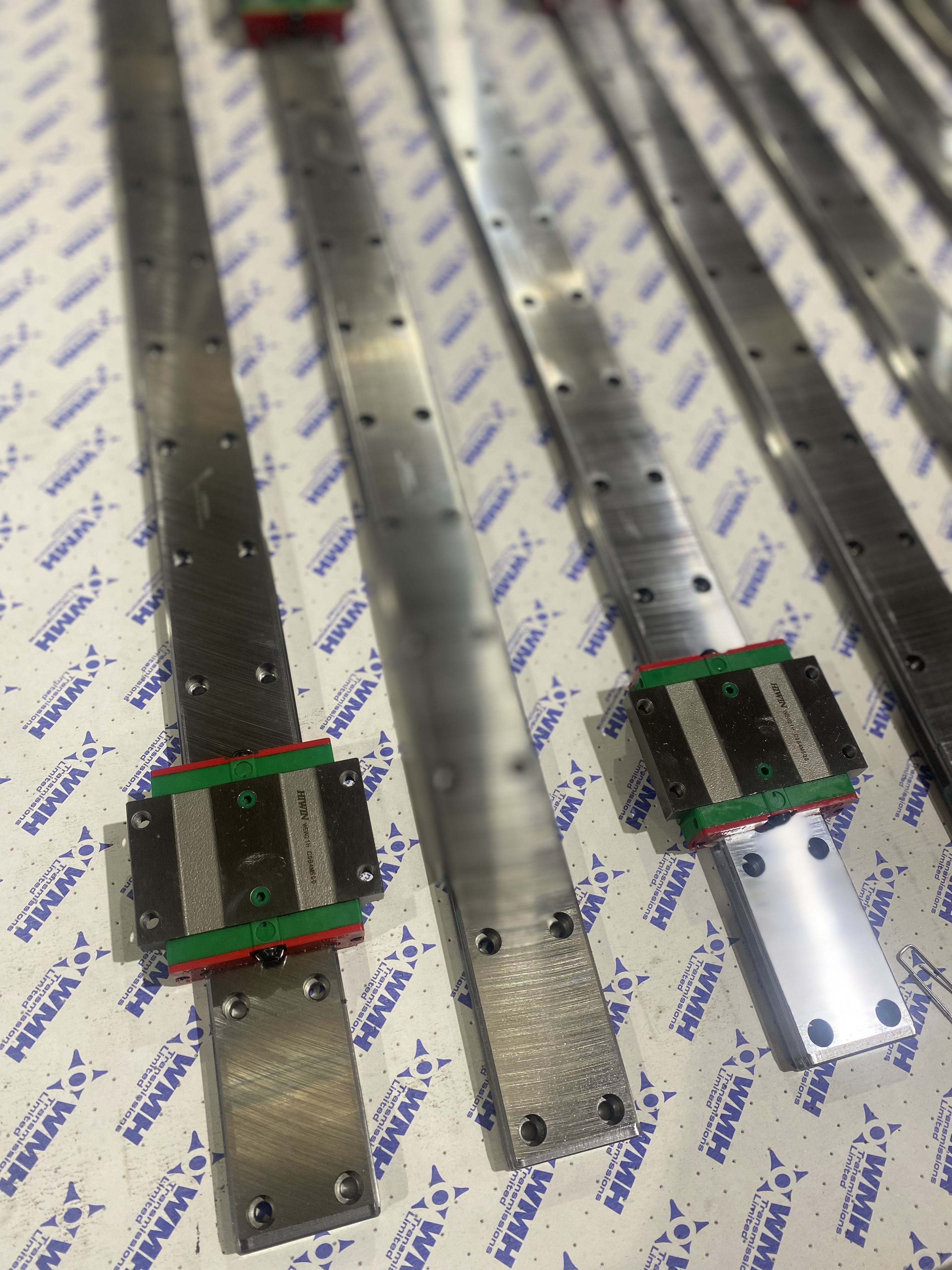

An end user had enquired from several suppliers about some specialised components that were found to not be readily available. Furthermore, these parts needed to be coated in a dust-preventative lubricant to ensure the quality and safety of the operations were not compromised.

The Solution

APEX Transmissions carries a varied and large range of stock, which includes the components that the end user required. After the in-store team picked the needed parts, they applied the specified performance lubrication to comply with strict health and safety regulations of the end user’s operations.

Within our stores team, we have experienced and knowledge-based technicians who can grease, sub-assemble and re-configure products in-house. This ensures that all products can be quality-checked and hand-packaged to ensure that you receive your parts in pristine condition.

The Result

Following the supply of the sixty linear block and rail assemblies within a 3-day leadtime, the end user was able to resume operations, saving maintenance costs and reducing downtime.

Our in-house service operations ensure that your project is undertaken to the highest of standards, allowing us to adhere to your requirements and schedules.

Key Results

Added value services e.g. lubrication coating applied in-house

Time saving operation achieved